In a warehouse in the New Mexico desert, a chunk of solid aluminum gleams in the flickering fluorescent light. Roughly the size and shape of the New York City telephone book, the aluminum could get shot all day with a high-powered rifle and give the marksman nothing to show for his work but a sore trigger finger. Yet this chunk has been violated. A plastic pellet, smaller than a walnut, has smashed a ragged five-inch hole right through the aluminum's center. It is a sobering sight and an object lesson for NASA's orbital debris program: The pellet, accelerated to 15,000 miles per hour by a powerful gun here at the White Sands Test Facility near Las Cruces, shows the violence a piece of orbiting space junk can wreak on a spacecraft. "In space, you can get relative velocities of more than 30,000 miles per hour," says Don Henderson, project leader ...

The Shooting Gallery

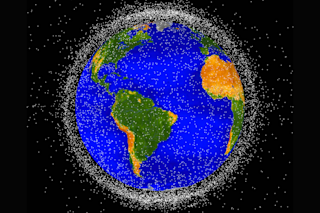

Orbital space around the Earth is full of deadly debris from old missions. Now NASA has to figure out how to keep a hail of space junk from bringing down the shuttle, the space station, and a lot of satellites

More on Discover

Stay Curious

SubscribeTo The Magazine

Save up to 40% off the cover price when you subscribe to Discover magazine.

Subscribe