This is a guest post from Melissa Lott, a dual-degree graduate student in Mechanical Engineering and Public Affairs at the University of Texas at Austin. Her work includes a unique pairing of engineering and public policy in the field of energy systems research. Melissa has worked for YarCom Inc. as an engineer and consultant in energy systems and systems design. She has previously worked for the Department of Energy and the White House Council on Environmental Quality for the Obama Administration. She is a graduate of the University of California at Davis, receiving a Bachelor’s of Science degree in Biological Systems Engineering. Melissa is also the author of the blog Global Energy Matters: Energy and Environment in Our Lives.

It has been almost two months since the Deepwater Horizon oil rig exploded and sank to the ocean floor in the Gulf of Mexico. Since then, a continuous stream of oil has contaminated our ocean and coastline, resulting in the worst environmental disaster in U.S. history. Efforts have been made to stop the flow of oil, but the solutions with the highest likelihood of success are still months from possible execution. This has left us with the troubling question of what we can do to minimize the negative environmental impacts of this oil. In particular, how do we clean up the massive quantities of oil already in the water? As it turns out, the answer to this might be found in Hollywood.

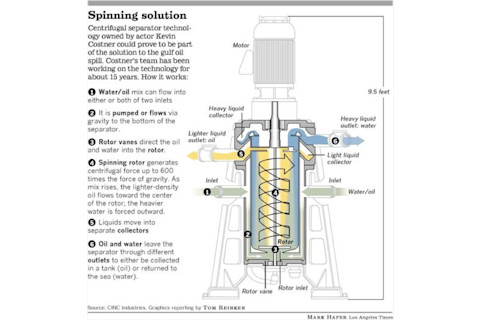

Kevin Costner, actor and apparent tech-aficionado, has a technology that is designed to quickly and effectively separate oil and water in order to minimize environmental damage from oil spills. Last Friday, the LA Times presented a lovely graphic (shown here) that illustrates and describes how this technology works in just six steps.

The final output of this machine consists of two streams. The first is 99% pure sea water, which can be directly piped back into the ocean. The second stream is 99% pure oil that can be stored onboard the vessels already at work in the Gulf. This could dramatically increase the effectiveness of these vessels in their fight against the constant stream of oil, allowing them to collect 99% pure oil instead of an oil-water mixture.

Costner’s technology isn’t new. In fact, he originally obtained the rights to develop and commercialize the prototype technology from the Department of Energy in 1992-93 via a technology transfer agreement. Since 1993, Costner has supported the development of this centrifugal separation technology by funding a business named Ocean Therapy Solutions (OTS) and its team of scientists. Today, the company has a series of five machines that can process 2 to 200 gallons-per-minute of contaminated water. Put another way, the largest of these models (the model V20) could likely remove 3,000 gallons of oil per day from the Gulf’s water.

What’s more, BP has already successfully tested these machines under “extreme” conditions and has signed on the dotted line to purchase 32 of them (presumably) for use in the Gulf. At least 31 of these are available for deployment today. Now, Costner and OTS are waiting for the oil giant to pay for the equipment before they deliver.

After nearly two months of feeling helpless, I am excited to hear about a technological solution that might help in the situation we have now - where the oil has already escaped and contaminated the surrounding environment. While this technology cannot stop the flow of oil or undo the damage already done to the gulf coast, it might limit future harm as we wait for the solution that will finally stop this oil leak.