Stuart Licht's STEP (Solar Thermal Electrochemical Production) process uses solar energy to break down atmospheric CO2 and other compounds into their constituent elements. These elements would ultimately be recombined to make plastics and fuel.

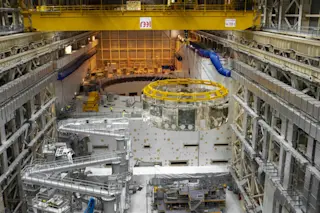

At the heart of the STEP process is an electrolysis cell, a device that uses electricity to break down chemical compounds. A prototype version of the cell, about the size of a fist, consists of two electrodes—positively and negatively charged—submerged in a chemical bath containing the target compound. When electric current passes through the cell, positively charged ions from the compound are attracted to the negative coil and negatively charged ions are attracted to the positive coil, splitting the material and yielding its constituent elements along with new compounds.

The hotter the contents of the cell, the less voltage required to initiate this reaction. Using heat from an external solar array, Licht, who's based at George ...