Scientists often turn metaphorical when groping for ways to describe their esoteric profession. Certainly that’s the tack Eric Johnson takes when trying to explain the work of his fellow biochemist and mentor Ed Schantz. Ed’s work is like fine wine making, says the 36-year-old Johnson. He can make this stuff in three weeks, but it’s taken him years of development to perfect his technique.

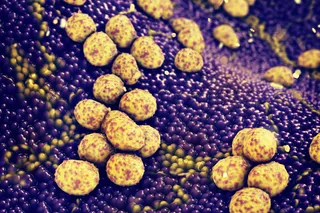

The stuff Schantz makes isn’t vino; it’s toxin. Specifically, it’s botulin, the toxin produced by the single-celled botulinum bacterium and the most poisonous substance in the world.

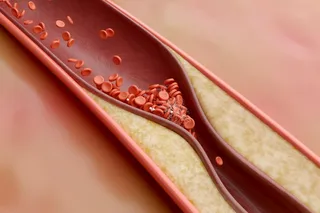

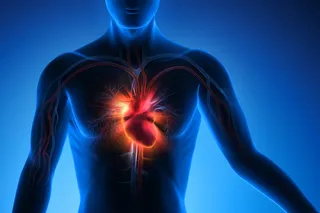

When ingested, botulin causes botulism, a form of food poisoning that can result in muscle paralysis and even death. But botulin has a good side also: in very small doses, it is an effective treatment for a whole class of human illnesses known as dystonias--uncontrollable muscle spasms that researchers suspect are caused by involuntary and excessive electrical impulses from ...