The materials human beings make and use have defined human history more succinctly than anything else. But now, in the midst of what some call the silicon age, it seems clear that the future epochs won’t be so easy to nail down.

“The big story in materials science is complexity,” says William Johnson, professor of engineering and applied science at Caltech. “There is more complexity now from many points of view: more constituents, more chemicals, more phases.” So while a Bronze Age metallurgist could stir together molten copper, zinc, and tin and call it a day, tomorrow’s breakthrough materials could require dozens of components in fiendishly precise proportions.

Fortunately, companies such as Symyx in the Bay Area of California are automating the discovery process. “So if you want a material that will emit pure blue laser light for an LCD screen, instead of going in the laboratory and trying to figure out what combination of gallium, arsenic, aluminum, and three other components would give you the best blue light, you can make thousands of combinations of those components and automatically test each one to see which is the best,” says Johnson.

Still, that approach requires that atoms arrange themselves. In a now-legendary 1959 lecture called “There’s Plenty of Room at the Bottom,” physicist Richard Feynman wondered, “What would happen if we could arrange the atoms one by one the way we want them?”

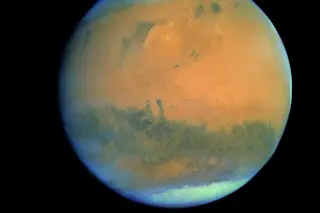

“New properties emerge when you can structure things at these size scales,” says Scott Mize, president of Foresight Nanotech Institute, a think tank that explores the practical side of ultrasmall-scale technology. Manipulating a wide variety of materials at the molecular level promises to deliver highly efficient solar cells, hydrogen storage that ushers in the long-awaited hydrogen-energy economy, human life-span extension, pervasive computing “so that every device is a smart device in one way or another,” better spacecraft, and possibly even a way to transform Mars into an Earth-like second home, says Mize.

It seems too good to be true, but the technology has already gone beyond blue-sky theorizing. Feynman dreamed of robotic arms that would assemble ever-smaller versions of themselves until they could place individual atoms like bricks in a wall (doomsayers have responded with the nightmare version: self-replicating tiny robots dissolving the world into “gray goo”). But researchers such as Angela Belcher of MIT are exploiting a promising shortcut—using viruses, bacteria, and yeasts to build electronic, magnetic, and optical structures.

Meanwhile, the game has just begun, and hype is everywhere. Johnson warns that basic chemistry is sometimes touted as miraculous micromanipulation simply because “there is something going on at the atomic scale in everything you do,” including dissolving sugar in a cup of coffee. Mize says that truly revolutionary materials science must involve the precise positioning and structuring of nanometer-scale particles—something that, at the moment, is less than practical.

In the science of manipulating molecules and atoms, we are “at the stage that computing was before the invention of the integrated circuit,” Mize says. “We have not yet had the big watershed breakthrough that changes everything.”

Boeing's plastic jet Airplanes have been made largely of riveted metal since Charles Lindbergh made the first nonstop solo flight across the Atlantic in May 1927. But Boeing’s 787 Dreamliner, scheduled for delivery in 2008, will consist of 50 percent composite materials—primarily carbon fibers embedded in resins—improving speed, cost, and comfort. Three versions of the jet will be outfitted to carry between 223 and 296 passengers.

Carbon laminate Epoxy resin, reinforced with carbon fiber and molded into shape, forms most of the fuselage’s exterior.

Carbon sandwich A layer of metal or glass between two layers of carbon-reinforced plastic adds strength in critical areas.

Fiberglass composite Used on the plane’s nose and at the junction of the wings and the fuselage.

Steel, aluminum, and titanium Used sparingly on the exterior as well as to form structural parts in interiors.