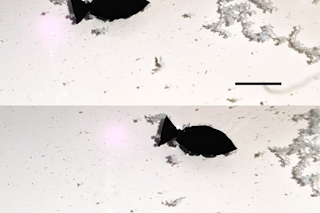

Peter will could see he was facing a serious problem. All around him things were shrinking. All kinds of things. When did this start? Why hadn’t he noticed it sooner? Growing up in Scotland in the 1940s, he used to take toys apart to see how they worked, but back then things were hefty—bicycles, typewriters, radios. Electronics started to shrink in the sixties and seventies, when he was a young engineer at ibm; but the machines at least stayed substantial, and the industrial robots he worked on were reassuringly beefy contraptions. By 1988, however, mechanical things were shrinking, too. Researchers had just built an electric motor 60 microns in diameter—60 millionths of a meter, .002 inch, less than the width of a human hair. When charged with static electricity, the rotor would actually spin. Pretty impressive, Will thought, but one thing bothered him. To build even one complicated machine that ...

The Incredible Shrinking Finger Factory

For years engineers have touted the future wonders of microscopic machines. But they have ignored a real-world-size problem: If machine parts dwindle to tiny specks, how will human or even robotic hands ever assemble them? One man's ingenious solution:

More on Discover

Stay Curious

SubscribeTo The Magazine

Save up to 40% off the cover price when you subscribe to Discover magazine.

Subscribe