Two floors above the crowds and traffic of Jay Street in Brooklyn, New York, Zivan Zabar and his graduate students are tinkering with their first coilgun, trying to get it to work. We haven’t fired it for a while, Zabar says apologetically. After a few more adjustments, though, the gun is ready. A three-ounce soda-can-size aluminum projectile shoots out of the upright, 16-inch-high plastic tube, flies a few feet, and flops into the hands of one of the students. In 20 years or so, says Zabar, a scaled-up version of his gun may be lofting satellites into orbit.

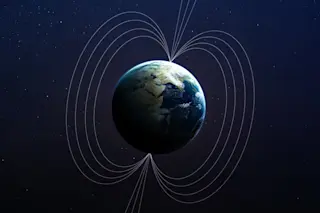

Zabar is an electrical engineer at the Polytechnic University in Brooklyn. His coilgun is an electromagnetic launcher, a device that accelerates a projectile by means of a magnetic field. The general idea isn’t new. For many years researchers have been developing a machine called a railgun as an alternative to rockets, which, because they must carry and propel their own fuel, are an extremely inefficient means of propulsion. In a railgun an electric current crosses from one rail, through the back of the projectile, to a parallel rail, creating a magnetic field that pushes the projectile along the rails and out of the gun at high speed--high enough, in theory, for the projectile to get where it’s going without fuel.

But railguns have problems. The powerful electric current heats the air between the rails to such high temperatures that the rails themselves are softened. After every few launches they have to be refurbished. What’s more, to launch a projectile at a speed great enough for it to reach the upper atmosphere, a railgun would have to be well over 1,000 feet long. That limits its practicality.

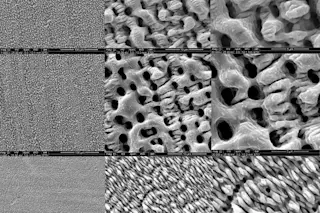

Zabar’s coilgun avoids these snags. Its barrel is a series of copper coils. The coils are energized sequentially, several at a time, by an alternating current that sets up a traveling magnetic field--a moving series of alternating north and south magnetic poles--on the inside of the barrel. This magnetic field induces strong electric currents in the aluminum projectile, which thereby acquires its own magnetic field.

The poles of the projectile’s field are offset slightly from those on the barrel, in such a way that a south pole, say, on the projectile is always being pushed from behind by a south pole on the barrel and pulled ahead by a north pole. As the barrel field moves forward, it drags the projectile with it. Unlike a railgun, then, which pushes the projectile only from behind, the coilgun applies force to the projectile all along its length. The bottom line is that for the same velocity and for the same projectile size, our coilgun can be made at least an order of magnitude shorter than a railgun, says Zabar. That’s the major advantage.

The other advantage is that the coilgun suffers less wear and tear. The projectile actually floats in the tube, suspended by the magnetic field, so it never even touches the coils. And because the current flows around rather than across the barrel, the air inside doesn’t get hot enough to damage the coils.

Zabar’s first gun, with the power turned up a little high, put a hole in his ceiling. Now he and his team are testing their third gun. It fires its shell across the lab and into a bucket full of rags at a blurry 500 miles per hour, about half the muzzle velocity of a shotgun.

The ultimate goal is a launcher able to put small payloads into orbit--or rather, into the upper atmosphere, where auxiliary rockets would kick in. For a projectile to be shot directly into orbit, it would have to leave the muzzle so fast it would burn up in the atmosphere. But even to reach the upper atmosphere requires a muzzle velocity of around 13,000 miles per hour. Zabar will need currents of a few million amperes in his coils, and high-speed switches able to handle such currents and energize the coils in a precisely timed sequence. Those switches do not even exist yet. It may take five more years, or ten, says Zabar.

But he is hopeful, all the more so since the Defense Department gave him a $2.5 million contract last fall. Zabar’s days of borrowing electrical equipment and buying aluminum tubing from Sid’s Hardware are over. We are a small outfit, he says. When we entered the game the railgun was already ten years ahead of us. But now people are looking very seriously in our direction. This machine promises to achieve what no other machine has accomplished.