In those devastating early days after the operation, Hugh Herr had a recurring dream. He was running through the cornfields behind his parents’ house in rural Pennsylvania, going impossibly fast, the sun and the wind on his face, almost flying. The ineffable sensation of freedom remains vivid decades later. Then the 17-year-old would wake up to the stumps of his legs below his sheets and remember: Both his limbs had been amputated five inches below the knee. The doctors said he would never run again.

They were wrong. Almost every other day for four years now, Herr, 46, has been jogging the 1.7-mile wooded loop around Walden Pond in Massachusetts on specially designed prostheses. “I was out just yesterday,” he says. “It’s a beautiful run.”

For Herr science is intensely personal. Before his accident, he was a world-class rock climber—but a C and D high school student who attended vocational school at night and “didn’t know what 10 percent of 100 was.” Today he has a master’s degree in mechanical engineering from MIT and a Harvard Ph.D. in biophysics, and he is walking around on motorized bionic limbs that adjust 500 times a second for angle, stiffness, and torque. He designed them himself.

In early 2011 his company, iWalk—headquartered near the MIT campus in Cambridge, Massachusetts—will release the PowerFoot One, the world’s first robotic ankle-foot prosthesis, to the general public. With an electric motor, five internal microprocessors, and a quarter-size inertial measurement unit that tracks and adjusts its location in space, the PowerFoot One is a giant leap over existing prostheses. It reacts to changing terrain and different walking speeds much like a natural human foot, facilitating a normal gait and allowing its users to push off the ground with seven times as much power as is possible with the best of its predecessors, all while expending less energy.

Herr, who directs the Biomechatronics group at the MIT Media Lab, spent the last eight years studying and refining computer models of the human leg to develop the PowerFoot. Bit by bit he has overcome most of its limitations. Still, there remains one stark difference between his invention and the real human limb: Herr’s prosthesis does not connect to the central nervous system, so the wearer cannot move it just by thinking. At least not yet. Sharing an ambition that would have sounded like science fiction just a few years back, Herr and a handful of other prosthetics engineers are now working to create lifelike limbs that users can control with their minds.

There are nearly 2 million amputees in the United States alone who could benefit from these breakthroughs. Most immediately, Herr’s inventions could soon enable the million-plus people who are missing lower limbs to do things they can now only dream of: Standing on tiptoes to pull a jar out from the back of a cabinet. Flexing their feet to put on shoes. Dancing.

That Herr is so close to achieving this dream is remarkable in itself. What is even more extraordinary is the path he trod to get there.

The first flakes had begun to fall when Herr and his pal Jeff Batzer headed into the wilds surrounding New Hampshire’s Mount Washington, the Northeast’s highest peak, to ice climb and hike in January 1982. By the time the teenagers turned to head back, just a few feet from the summit, the wind was gusting at up to 94 miles an hour, visibility was less than 10 feet, and the temperature had fallen below zero. The two became disoriented and headed in the wrong direction.

It was three days before a woman in snowshoes stumbled upon the boys’ tracks and found them huddled and frozen, hours from death. By then, an avalanche had claimed the life of a searcher, and both Herr and Batzer had severe frostbite. Doctors amputated four of Batzer’s fingers, a thumb, his left foot, and all the toes on his right. Herr wasn’t as lucky.

His first prosthetic legs were made of plaster of paris. The prosthetist who fitted them suggested he might one day be able to walk without canes. But nothing could keep Herr from the climbing wall. Seven weeks after doctors amputated his lower legs, he hopped in a car with one of his older brothers, Tony, and headed to a series of cliffs along the Susquehanna River. For years he had been doing things on rock faces that people said he couldn’t, but even he was amazed by his performance that day. Weak and recovering from the surgeries, Herr was wobbly on his new feet. On the rock wall it was a different story. “I felt more natural scrambling on all fours than walking,” he says.

By spring Herr was in a local machine shop experimenting with his artificial limbs. Every few weeks he headed to Philadelphia to meet with prosthetist Frank Malone for refittings and adjustments. Herr began tinkering with the design of his new legs, adjusting the length and playing with different materials to make them lighter. “I realized that my prostheses need not look human,” he says. “They are a blank slate: I could create any prosthetic device I wanted for form, function, and enhancement.”

Herr threw out his climbing shoes and glued climbing rubber directly to the bottom of his mechanical feet. Then he went to work on their shape. For expert pitches where he planned to stand on small rock edges the width of a dime, normal feet were a disadvantage. So he designed a prosthetic about the size of a baby’s foot. He created a pair of feet with toes made of laminated blades that he could jam into tiny rock fissures far too slim to hold a normal human foot. He made the height of the legs adjustable; at 7 feet 5 inches, he could reach handholds and footholds far beyond the range of any able-bodied climber. And he made his legs easier to move. Herr drilled holes throughout legs fashioned from aluminum tubes, making them so light that they just barely supported his weight, while increasing the number of pull-ups he could do and the distance and speed with which he could climb.

“From that personal experience, I realized that technology has an extraordinary capacity to heal, to rehabilitate, to augment, and that really set the tone for my entire professional life,” Herr says.

He spent a couple of years traveling and living in the climbing meccas of North America, burnishing a reputation for his skill that eventually won him a spot in the national Sports Hall of Fame. But even as Herr excelled on rock walls, he was increasingly frustrated with what he could do on the ground. His rigid prosthetics lacked the natural cushioning provided by the tendons of the ankles and feet. The sockets where his legs met the artificial limbs chafed when he walked, leaving him raw and bloody and putting powerful strains on his knees.

By 1985 Herr had had enough. When the doctors said no solution existed for the problem, his experiments moved beyond climbing feet and into the realm of medical devices. “The medical community was giving me these devices and saying, ‘This is the best, live with it,’” Herr says. “I just couldn’t accept that what they gave me was really the best that we could produce.”

First he tried stuffing the sockets with leather and rubber to cushion them. Then Jeff Batzer, his fellow Mount Washington survivor, introduced him to a prosthetist and orthotist named Barry Gosthnian. Gosthnian had been an Air Force mechanic in Vietnam and recalled the shock-absorbing hydraulic supports used in aircraft landing gear. Perhaps, he suggested, a hydraulic cushion of some sort could soften the impact in the socket.

Herr and Batzer toiled in a workshop to develop a better hydraulic socket. That fall, Herr enrolled at nearby Millersville University, a state school in central Pennsylvania. With a new reason to study, he developed a passion for math and physics, earning almost all A’s.

By the time Herr graduated from college, he had his first patent—shared with Gosthnian—and a prototype for a cushioned socket with inflatable bladders. The bladders, made out of soft, flexible polyurethane membranes, were located wherever weight-bearing portions of the leg stump pressed against the socket, cushioning the force and softening the pressure on the stump as needed. (His primary research subject? Himself, of course.) He also had an acceptance letter to a graduate program at MIT in mechanical engineering.

Seeing Herr stride casually across MIT’s campus in a rainstorm, wearing blue jeans and a pair of Italian leather loafers, it’s virtually impossible to tell that he is missing both lower legs. He moves with a seamless, flowing gait—hands in the pockets of his puffy, green jacket, his gaze roaming the grounds. But in his lab, Herr often goes shoeless, his pant legs hiked up to expose aluminum legs an inch in diameter atop sleek masses of silver gears and wires, which power flat black feet resembling the bottoms of flip-flops. “I think they are more attractive than human legs,” he says.

Herr began work on the PowerFoot about six years ago with a simple realization: No available prosthetic came close to replicating the beauty and simplicity of human locomotion. Even with the best available models, most amputees walked more slowly and had less balance. Their gaits were eccentric, and their devices often caused back problems. When a person with intact lower limbs walks, the amount of power the calf muscles expend increases with walking speed. Yet virtually all commercially available ankle and foot prosthetics are passive devices, containing spring mechanisms to absorb shock as a person walks but making no effort to replace the power-generating capabilities of the muscles in a person’s lower limbs.

Herr and his collaborators believed that the lack of ankle power was one of the main reasons amputees burn 30 percent more energy walking than do humans with intact lower limbs. Addressing that problem would be no easy task, however. “At the time Hugh started this, if you had asked anyone in prosthetics, they would have told you that the ankle requires so much power that you could not build a lightweight, compact, quiet one,” says Bruce Deffenbaugh, a longtime researcher at the MIT Media Lab who worked on the project. “But Hugh is unstoppable.”

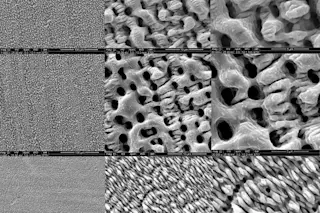

Herr and his partners began collecting all that was known about the dynamics of the human leg and the interaction of its component structures. Where the literature was sparse, they tried to fill in the blanks by taking precise measurements of a healthy human leg and creating a mathematical model that spelled out how the different components of the leg interact. They had to ask fundamental questions about everyday behavior. How much power, for instance, does a normal calf muscle in a 5-foot 9-inch male generate right before the foot pushes off the ground? When that muscle flexes, how will it affect the stiffness of the tendons attached to it? How stiff is the ankle when a person attempts to slow down?

While creating this mammoth mathematical description of a leg at work, Herr set out to build a robotic prosthetic able to mimic the human foot and ankle. To replicate the ankle’s natural ability to brake when walking downhill, he modified a previous invention he had created to control the stiffness of a prosthetic knee. The device contains sliding steel plates separated by an oily liquid that grows thicker when a magnetic field is applied. Electrical sensors measure both the angle and the force applied by the user on the ankle, and a computer modifies the strength of the magnetic field accordingly. Then, to determine the ankle’s location in space and to adjust the angle of the prosthetic foot appropriately (if, say, a person’s foot is suspended in midair going down stairs), Herr incorporated the same sensors used in guided missile systems.

By 2005 Herr’s lab had produced its first portable, motorized foot and ankle prototype and had demonstrated that the device could replicate the feel of actually walking. But the big challenge of powering the prosthetic remained unsolved. The prototype was connected to a backpack containing almost 13 pounds of electronics that amplified power coming from a wall socket—not a practical solution for an amputee on the go. Herr’s graduate students spent months trying to reduce transmission losses and cut back on energy costs but could not come close to creating a motorized ankle small enough and powerful enough to match a real one.

Meanwhile, Herr continued working on what would prove to be key to the solution: springs that use the same principle as the human leg. Human tendons and ligaments contain springlike fibers that store, release, amplify, and redistribute the energy we use when we walk. “The body uses springs to reduce the work the muscles have to do,” Herr says. “The human leg is filled with them, and there is this elaborate energetic flow. Energy is constantly being shuffled from tendon to tendon to tendon.”

Early on, Herr had concluded that a small motor alone would not be capable of delivering adequate energy quickly enough to replicate the burst of force with which the foot pushes off the ground when we walk. But if the motor gradually fed energy into a spring, the speed of energy production wouldn’t matter. When it came time to push off, that spring could release all that pent-up energy at once, propelling the human foot off the ground with the explosive force of a natural human ankle.

Herr’s lead graduate student on the project, Samuel Au, spent months tinkering unsuccessfully with the motor. Then Herr realized that none of the versions of the motor incorporated the secondary usage of tendons that happens in a real ankle joint. Perhaps the solution was to add more springs, this time in parallel with the motor.

The hunch paid off. The secondary springs reduced the amount of force required by the motor, mimicking the calf muscle’s usage of the Achilles tendon, which allows the calf muscle to provide power without contracting. When Herr put on the reworked prototype and began shambling down a walkway in the lab, a broad smile spread across his face. He picked up his pace, walking faster and faster. By the time he announced that the ankle felt “just the same as walking with a normal ankle,” the lab assistants were cheering.

Making full use of this newly reconfigured web of springs, the lab soon doubled the power emanating from the battery in the small motors in PowerFoot One. Today when Herr walks, a motor in the back of each foot gradually feeds energy into a combination of springs inside the foot. Some of the energy is released when he simply pushes off the ground. If he climbs a hill or picks up his pace, the motor and the springs release more energy, as required.

“That,” Herr says, “is just how the body works.” He and his team have added other touches to the PowerFoot One that replicate the way the tendons in intact legs function. When a person steps in a pothole and pressure on his leg increases, nerves at the back of the human tendon detect the change in the springlike fibers and send a signal up the spinal cord, which instructs the calf muscles to power more forcefully. When Herr steps in a pothole, sensors attached to elastic structures in his PowerFoot do the same thing. They detect the added pressure and send the information to a computer chip. The chip’s software tells the gears of the foot to push off the ground with more force to compensate. “Even though it is made of aluminum, silicone, and carbon, it behaves as if it were flesh and bone,” Herr says. “If you put nature in the machine, the biological body attached to it will be familiar with those dynamics and adapt comfortably.”

Herr has tested the leg at the state-of-the-art Gait Laboratory in MIT’s Computer Science and Artificial Intelligence building, donning a mask that measures his oxygen consumption and carbon dioxide exhalation to calculate how many calories he is burning. Sensors attached to two- by four-foot floor plates precisely measure the force he exerts when he walks, dances, or runs. At the same time, cameras around the room track 30-plus reflective markers affixed to well-defined anatomical locations across his body. They capture variables like knee and ankle angles and joint torque. All the data are synced up and compared with similar data taken from a subject with intact limbs performing identical tasks.

“I am an amazing experimental model because if you put robots below me, we can actually test hypotheses,” Herr says. “If my body responds as if I had intact lower limbs, then that would suggest our theory is robust. If my body responds in a pathological way, it suggests our theory needs work.”

But the more powerful evidence of the device’s utility is revealed in the response of some of the subjects from outside the lab who have tested out the ankle, and their loved ones watching them walk. Often they start to cry.

“It can be very emotional,” Herr reflects. “It can feel like you have your biological foot back.”

The U.S. Department of Veterans Affairs (VA) has been the prime funder of Herr’s work on the PowerFoot One and has enlisted returning vets to test out the device. Not surprisingly, the people who have so much to gain from Herr’s achievements are also the ones financing his plans to take them a radical step farther—linking bionic limbs directly to the human nervous system.

That goal is not as outrageous as it would have sounded a few years ago. At Brown University, just a couple hours’ drive from Herr, neuroscientist and engineer John Donoghue is developing a brain-computer interface known as BrainGate. This revolutionary device literally creates a direct connection between man and machine.

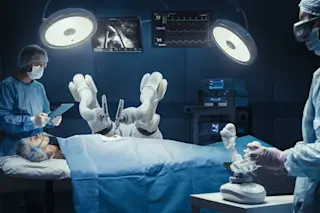

Donoghue and his team have surgically implanted miniature electrodes in the brains of five patients who had injured spinal cords or who had suffered stroke or disability from ALS. The sensors can register neurons firing in the areas of the brain that generate movement commands. In a healthy person, such neural impulses would be transmitted through the spinal cord down to intact limbs and would signal them to move. The BrainGate’s sensors instead transmit the impulses to a plug attached to the top of a patient’s head, which passes the commands on to a computer that can translate them into signals controlling a robotic arm.

Herr is taking a slightly different approach, developed in conjunction with two other leaders in the effort to connect nerves and machines: Richard Weir and Todd Kuiken, both of Northwestern University and the Rehabilitation Institute of Chicago. Unlike the BrainGate researchers, who are trying to tap directly into the brain, Weir and Kuiken are attempting to pick up impulses coursing through the nerves and muscles that remain in the parts of amputee limbs that remain intact. For instance, the nerves that once sent signals to Herr’s ankles and feet are still there, ready but unable to deliver volitional signals to the missing limbs.

To get at the data, Kuiken has developed a technique he calls targeted muscle reinnervation. Surgically, he connects those orphaned nerves to other muscles—like the muscles that remain below Herr’s knee. Once connected, those muscles contract in response to signals from the brain meant for the absent limbs. Electrodes attached to the skin just above those muscles pick up the contractions and send a signal to the PowerFoot. Computer software then tells the artificial foot to flex as intended.

Kuiken has already used this technique successfully on upper-limb amputees. One subject, Jesse Sullivan, lost both arms at the shoulder. Kuiken took the four main nerves going to his arm and transferred them to his chest muscles. Sullivan is now able to close the hand of a commercial prosthesis simply by thinking about closing his hand. The thought causes muscles in one part of his chest to contract, which the computer translates into the appropriate movement of the prosthetic arm. Thinking about bending his elbow causes contractions in a different area of Sullivan’s chest.

“As the human-machine interaction becomes more sophisticated, we will see fewer and fewer disabilities. One day I will truly no longer be disabled and maybe augmented in some ways.”

But relying on electrodes attached to the body has limitations. “If I were to go run a mile right now, I could fill this glass with sweat,” Herr says. “It’s difficult to imagine an electrode being able to get any type of signal at all in that environment.” He believes that implanting a wireless sensor inside the body is a better solution. Weir has developed such a device, called an Implantable Myoelectric Sensor, or IMES, which he has been using to develop artificial hands.

The VA is funding a collaboration between Herr and Weir, intended to let amputees easily and subconsciously control the PowerFoot using IMES. The two hope to make a small incision in a human leg and implant two microchips in what remains of the muscles leading to the front and back of the calves. The chips would pick up muscle contractions inside the leg and wirelessly transmit a signal to the PowerFoot that would instruct it to move the prosthetic ankle.

Weir has already safely inserted IMES into the forearms of monkeys in the laboratory. Within the year, he and Herr hope to use part of their VA grant to win FDA approval for a human trial. “If we get it into people and it proves efficacious, it will have a huge impact on how prosthetic systems are designed and controlled,” Weir says. “We’ll have the ability to design much more advanced systems.”

In the original grant application for IMES, Herr had proposed that his colleague cut him open and perform the surgery. The VA didn’t go for it. “The reviewers thought that I would bias the data because I would so badly want it to work,” Herr says, clearly irritated, “which is odd in my opinion because we are going to use another bilateral amputee. But if it’s successful I will certainly get them. Ultimately many, many amputees will be implanted.”

New technology will also usher in new attitudes, Herr hopes. It was not so long ago, he points out, that the visually impaired were viewed as disabled. Today glasses are so ubiquitous that nearsighted people are no longer seen as handicapped. Soon it may be the same with prosthetics. “Right now, well over half the world’s population has some condition, and because of poor technology, society considers those conditions disabilities,” Herr says. “As the human-machine interaction becomes more sophisticated, we will see fewer and fewer disabilities. One day I will truly no longer be disabled and maybe augmented in some ways.”

The way Herr talks about rock climbing in northern Italy’s Dolomites or going for a hike in the wilds of New Hampshire, that day seems just around the corner.

THE BATTLE TO BUILD A BETTER LIMB

Hugh Herr’s work with PowerFoot One is just the most dramatic in a series of advances that are reverberating through the field of prosthetics. A major factor behind this scientific surge is war. The conflicts in Iraq and Afghanistan have sent home thousands of maimed soldiers and unleashed a flood of research dollars to help them. The U.S. Department of Veterans Affairs’ funding for “classic prosthetics” rose from $5.2 million for 21 projects in 2006 to $9 million for 38 projects this year. After Bush administration officials raised concerns about the large number of soldiers returning from Iraq as upper-limb amputees, the Pentagon’s Defense Advanced Research Projects Agency (DARPA) shelled out $130 million to develop its Revolutionizing Prosthetics Program. This includes funding for the DEKA Research and Development Corporation—a company founded by Segway inventor Dean Kamen—to develop an advanced robotic arm that would allow an upper-limb amputee to “pick up a raisin or a grape,” Kamen recalls.

For decades, even the most advanced upper-limb prostheses could perform just a few movements. Kamen’s eight-pound appendage, nicknamed Luke after the Luke Skywalker character in Star Wars, contains a suite of microprocessors and advanced electronics that respond when amputees flex their shoulders or press buttons built into shoes. Luke contains six user-selectable hand grasps that allow the wearer to perform a variety of everyday tasks, such as clasping keys, turning doorknobs, or pulling the trigger on a tool. It also has a device that vibrates on the skin to signal the strength of the user’s grip. Fred Downs, who heads the prosthetics program at the Veterans Health Administration and who lost his left arm during combat in Vietnam, recently tested Luke for two weeks. “I did things I haven’t been able to do for 42 years,” he says. “I could hold a cup and drink—using my left arm.”

In a complementary project, the Defense Department’s Telemedicine and Advanced Technology Research Center (TATRC) recently contributed $3.6 million toward the development of an advanced prosthetic knee. And last year the U.S. Army Medical Department began providing some amputees with the X2, an artificial knee that allows the user to walk backward, ride a bicycle, and climb stairs with ease. The knee is produced by Otto Bock, a German company that developed a groundbreaking computer-controlled prosthetic leg in the 1990s called the C-Leg. The C-Leg relies on microprocessors and sensors to adjust stance and knee movements. The X2 knee can determine its location in space and calculate how fast the wearer is moving, even if he or she is stepping over an obstacle.

The next-generation X3 knee, also produced by Otto Bock, will be capable of operating in seawater and sand, according to TATRC, making it possible for soldiers who have lost a leg to continue serving in the field if they choose. All of these advances will also help millions of amputees who have never seen combat. The X3 will be commercially available in fall 2011.