Crowning the plethora of issues with the last Transformers movie, Michael Bay notwithstanding, was the programmable matter — matter that can change its physical properties autonomously, or based on instructions from a designer. Bay’s take on it, transformium, is a new pop-culture reference point for programmable material (when, on the spectrum of fantastic self-assembling robot bodies, Terminator was objectively more realistic). Bay also overlooked the wide array of applications the tech could have, in addition to shape-changing. But most of all, it just seems a bit unrealistic for matter to just take on new physical properties just by changing shape...until now.

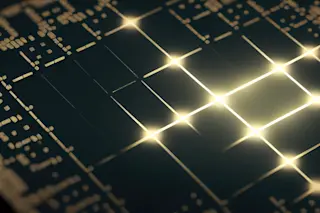

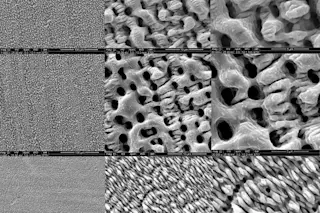

As it would turn out, researchers at Purdue, have been working on a way to make matter do just that — though not for the purpose of making giant robots. Rather, the researchers have created new types of lattices that can be tuned to adopt new physical properties, through ...