At a pessimistic time when “development” is often taken as a euphemism for environmental destruction, architect William McDonough offers an optimistic possibility: What if our buildings and the materials used to construct them could make the world a better place? As one of our most forward-looking architects, McDonough has racked up three U.S. presidential awards and numerous blue-chip clients by delivering on that seemingly radical hope. He calls his design philosophy Cradle to Cradle—a vision of a continuous cycle of use and reuse of materials without any waste. He hopes to create a new Industrial Revolution through sustainable designs. The former “green dean” of the University of Virginia School of Architecture, McDonough has parlayed his thinking into the influential book Cradle to Cradle: Remaking the Way We Make Things, an international movement, and a thriving business.

As realized by William McDonough + Partners, his architecture and community design firm based in Charlottesville, Virginia, McDonough’s projects have garnered wide acclaim. Ford Motor Company gave him $2 billion in 1999, with which he transformed the company’s ancient Rouge complex in Dearborn, Michigan, into an icon of green design, complete with the largest living roof on the planet: a 10.4-acre assembly-plant roof blanketed with sedum, a drought-resistant ground cover. The firm has done similar work for Gap Inc., Herman Miller, Oberlin College, and Chicago’s city hall. McDonough has also recently drawn up plans for a number of new, ecologically friendly cities in China. Separately, MBDC (McDonough Braungart Design Chemistry), the company he cofounded with German chemist Michael Braungart, consults on the creation of healthy products and processes, such as utilizing sustainable materials for Nike sneakers.

DISCOVER caught up with the architect and designer at his Charlottesville office.

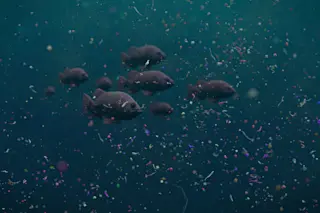

How do you see the future of architecture and design? Given the obvious concerns for human ecological health—in terms of climate change, heavy metal toxification, indoor air quality, air pollution, plastics in the oceans, and things like that—there will be a large-scale trend to buildings that start to act like organisms. The green-roof movement, for example, will be promulgated so that buildings make oxygen. We’ll also see roofs that make energy, as in solar energy. In effect, the buildings will become photosynthetic and make either oxygen or energy, or both. We’ll see materials that are derived from healthy sources and are designed for reuse and recapture.

What kinds of healthy materials will we be using? Well, sustainable forestry, recycled metal, things like that. They’ll be characterized in terms of where they were sourced. Right now when you order wood, you don’t necessarily know where it came from. If you order metal, you don’t know if it’s recycled, you don’t know where it came from. But I think in the future, materials will have passports. We’ll know where they came from and where they’re going.

Why is knowing the origins of your materials so important? Because in the current system, we take, make, and waste. Things come from just about anywhere, get used, and then get taken to the landfill or are incinerated when we’re finished with them. And it won’t be possible for 8 to 10 billion people on the planet to celebrate a high quality of life if we deplete all the resources in a flawed cradle-to-grave system. When we look at things like plastics, they should be seen as what we call technical nutrients. They should be materials that get used over and over again for lots of different purposes over time, rather than being used once and then buried or burned.

What do we need to do to realize this vision? We need to adopt the Cradle to Cradle approach in the design and deployment of products and systems. It would mean, for example, in the United States, that we take recycling seriously. Right now we don’t have curbside recycling in half of America. And a lot of the materials that are “recycled” are basically being baled up and simply sent to China, where they’re burned or, in the case of paper, made into packaging. We need a recycling consciousness. The other thing we need is to recognize that renewable energy is potentially the largest job-creation program in the history of the planet. The conversion to renewable power in all its forms—wind, solar, et cetera—will create indigenous jobs because these forms of energy are inherently local and are not exported. In the deserts, for example: solar thermal. In the Great Plains: wind. Once we become aware of that, we’ll realize that not only will we be getting energy security, we’ll be getting job security as well, on a global basis.

What are the obstacles to a full-scale embrace of renewables?The biggest obstacles are short-term thinking and a short-term economic framework. As soon as you see some of the longer- term economic drivers become part of the short-term decision making, you can see the transformations. A really good example of the future in the present is Masdar, this new city that’s going to be built in Abu Dhabi. They’re investing billions of dollars in solar right now. When you see the oil countries investing in renewables, it’s a sure sign of something happening that relates to their perception of what the long-term situation will look like. It’s not to say that we’re running out of oil. It’s to say that there’s a new economic opportunity that can be taken advantage of. And it is now cost-effective thanks to the high price of oil.

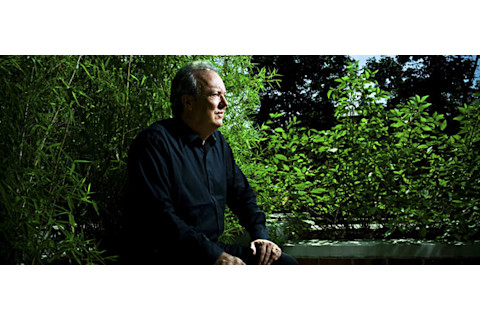

NULL | photo by Stephen Voss

You are bringing your philosophies such as Cradle to Cradle to China. How is that playing out?Chinese leaders are concerned about the loss of farmland due to rapid urbanization. That’s why we, on a conceptual level, posited the idea of putting farms on the roofs in cities. These are concepts that are now sort of floating around in the consciousness of the design community. And I think what needs to happen in order for something like that to actually get built would be for the Chinese to recognize the dire nature of their circumstances and to see this as one of the options that they can take on.

Looking back at your career thus far, what do you consider your greatest successes?Buildings such as the one at Oberlin College [the Adam Joseph Lewis Center for Environmental Studies], which was an experiment—a tremendous amount of ambition for a really small project. Trying to make a building like a tree that makes oxygen, sequesters carbon, produces more power than it needs to operate, and purifies its own water—things like that. That’s really been tremendously inspirational for us here. I think getting the Ford roof built was a big success. It was a testimony to putting together a huge team of people focused on the same thing.

Ford’s Rouge complex is huge—at one point it built nearly every part of the Model T. How do you approach such a massive project?We approached it from a principles perspective. Instead of starting with goals or with tactics or conventional practice, we started with the idea that this was a place that was essentially an unhealthy workplace as a result of years of Industrial Revolution activities. And so we started with the idea of a healthy workplace. What would that be? From that principle grew the question of how would you have healthy water? How would you have healthy soil? How would you have healthy air? All of those pointed to the idea that you could use nature as the mechanism for creating those conditions. When we looked at the size of the roof, we said right now, as far as the planet is concerned, that would be a liability if it were an impervious surface. Because it would just create stormwater problems, it wouldn’t create habitat. It would create heat in the summer when you wanted cooling. It would perform all sorts of things, but it wouldn’t be regenerative. It would be degenerative.

It became clear to us that a large green roof would be a marvelous thing, because it would make oxygen, change colors with the seasons, protect the roof from thermal shock, absorb stormwater, absorb particulates, solve a lot of the problems that a regular roof wouldn’t even begin to address. And so the question became, could we afford it? That’s where we had to put a big team together and do research. We went to study the green roofs of Europe and essentially found that lightweight, low-maintenance green roofs had been developed in East Germany during the cold war as camouflage for aircraft hangars. We could import that technology because it was lightweight and cheap and apply it to an American industrial shed building.

What is so special about the East German roof design?It’s only an inch and a half thick. And it’s made of exploded shale, so it’s stone with sedum growing in it. That’s a low-growing succulent plant, a noninvasive species that is very drought tolerant.

How are you applying what you’ve learned at Ford to your current projects, such as what you’re doing in China?One way is that on large-scale projects we are now able to propose to clients that they use green roofs, because since we’ve had the opportunity to do one that big, we can say it’s possible. So that is giving license not just to us but to a whole profession, to propose large things like this, large-scale green roofs all over, which is really what we were hoping would happen as the result of our work.

What is an example of something you would do differently in the future?The thing that I would do differently in a place like China is this: I would go for planted roofs with container gardening for food growing. The difference as we moved ahead is, we realized that not only could a roof absorb stormwater and things like that, but it could actually be a farm. I think the next generations of green roofs will be gardens and farms.

How do you see such urban farms working?Well, they’ll require heavier weight, so it’s hard to do on lightweight, industrial, low-cost buildings. I think that we’ll see thin green roofs or solar collectors on lightweight industrial buildings. But then on residential buildings, where you already have the structure, I think we’ll see things like pot gardening, you know, big planters with vegetables and things growing in them.

You have gotten involved in designing durable goods that can be disassembled and reused. What are the coming trends in this area, and how has it changed since you began those types of projects? The delightful thing that’s happened is that most of the examples we have worked through in terms of changing the design of products have resulted in cost savings for the producers, because the products get simpler. If they’re designed for disassembly, oftentimes their assembly becomes simpler. For example, if something is screwed together with 50 screws, when you stop and think about having to take it apart, you start to question every screw. And you start to wonder why things couldn’t clip into each other and get held together by one screw instead of five screws, things like that. So all of a sudden the whole idea that you would take something apart makes the design of putting it together simpler. Another thing we’ve found [in designing goods for reuse] is that we’ve reduced regulations by looking at all of the chemicals that go into products and using chemicals that are safe.

Can you give an instance of how you’ve reduced regulation? Textiles is a good example. In textiles we’ve looked at thousands of chemicals. By using only the ones that are safe, we find that the product doesn’t need to be regulated, because there’s nothing there that’s dangerous. Take, for example, a textile from the manufacturers Rohner and Designtex, where we used 38 chemicals instead of the hundreds that would be used normally. What happens is the water coming out of the textile mill isn’t contaminated. And the product itself isn’t contaminated. So all of a sudden the whole regulatory environment is changed. You don’t have to handle materials specially because they’re dangerous. You don’t have to file lots of reports on your handling of various materials because you’ve essentially removed them from the design frame.

How can we spread this approach so we seriously cut back on the use of dangerous chemicals? On the design side, there are a lot of tools that will be in the hands of designers. So if somebody’s deciding they want to make some plastic red, we’ve already cataloged the different reds that aren’t dangerous that could be used for plastics. A designer can quickly access the database with these ingredients that are positively identified, so you don’t just say, “Give me plastic, and make it red.” You can say, “Give me this plastic because it’s recyclable, and make it that red because it’s safe.”

What lessons did you learn when you were creating sustainable product designs for Nike? I think seeing your customer as part of your family is really important, seeing that you’re in a relationship with your customer when you sell them a product. And it’s not an abstract thing; there is a physical transaction that’s occurring that has an emotional connection.

So, for example, say I sold you a pair of shoes, and now you’re finished with them and they’re these sweaty old crummy things. What are you supposed to do with them? It would be easy to throw them in the wastebasket, just throw them out. But if you’re part of the family, you could say, “Well, maybe I’m going to get some money back from these shoes. I could get a discount on my next pair if I bring them back.” And you could ask, “Why would a company give a discount in exchange for old shoes that they then have to grind up or recycle and take care of? It’s really just a cost.” But the fact of the matter is, companies like Nike could really be seen as companies that provide shoe services. In fact, they’re servicing your needs for foot coverings. They can also be seen as design and marketing companies. They’re not really manufacturers. They job out manufacturing. So, if 75 percent of a company’s budget is marketing and you develop a way, through the actual materials of the shoe or the product itself, to have the customer come back to you for their next product, then it makes recycling look like a real small part of your marketing budget. And all of a sudden the product becomes part of your marketing for the next generation. That’s the real value in this. It’s not going to be the molecules and the value of those molecules per se. It’s the relationship between the customer and the supplier that is the valuable thing.

You’ve been called a utopian. How optimistic are you now? I think we have to stay optimistic if we’re designers, because designers wake up every morning trying to make the world a better place. So the idea is to say, “Things could be better if we apply ourselves in different ways.” On the one hand designers are optimistic that, as a species, we’ll rise to the occasion and see that we have a fundamental design flaw: We don’t recognize that our processes could integrate with natural systems in delightful ways instead of destructive ways. So I’m optimistic that we’ll smell the coffee at some point and start to rise to the occasion. As far as whether it’s too late or not, there are certainly harbingers of doom and gloom everywhere that we see and hear about on a daily basis. It sounds like the train has left the station on a lot of these things. And a lot of these things are going to take decades to transform and to heal. The climate change and melting [of glaciers and polar ice] issue is obviously something that’s apparently under way and cannot be turned on a dime. These things are going to take decades to clean up and reverse. That will be done by design.